Your Cart is Empty

*** Free Shipping for orders from £ 50 ***

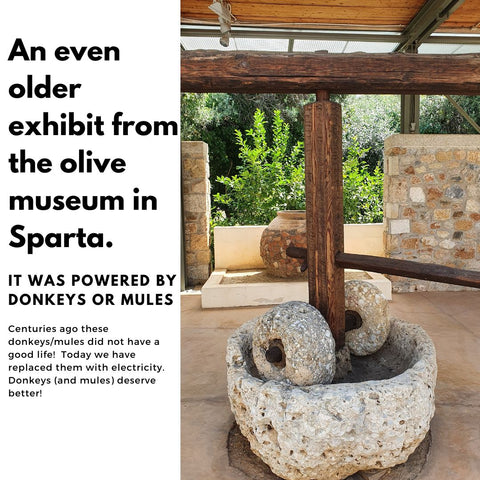

Milling has greatly evolved in the last 100 years and olive mills come in lots of different variations. Long gone are the days of stone grinding (stones cannot be cleaned well) and pressing oxidised olive paste in grimy, mouldy sacks exposed to more rancidity (unhygienic and inefficient).

Now there are state-of-the-art, squeaky clean olive mills with the highest certifications for hygiene. Anything that comes in contact with the olives or oil that is not supposed to be there has a negative effect on the quality of the oil. It costs money to keep a mill clean and up to date. But a clean mill is kept in business profitably and that can go on producing to high standards and continuously evolving in positive ways.

Then there are the mills that have not been renovated in years and have all the accumulated grime of ages of neglect. These are simply not run professionally, they are an afterthought, not economically successful and in a vicious cycle of neglect and business failure, often only shored up by EU subsidies (in the EU olive-producing countries like Greece). They will process olives at a bottom dollar low price, but will equally produce bottom level quality. Olive oils that leave a sludgy residue at the bottom of the bottle come from such mills. Several stages of a quality production process have been completely left out in these mills, some of which are:

* selecting out and discarding rotten or infested olives,

* meticulously washing the fresh olives,

* properly monitoring, calibrating and optimising temperatures and timings of pressing,

* separating out leaves (large amounts of these are often left in intentionally, to give the oil a greener colour with their chlorophyl and to help cover up how unclean it is, they don't add value otherwise)

* filtering out solids, that when left in, oxidise the oil within just a month or two of production, turning it into the unpleasant product many consumers in the UK have sadly become used to and have often chosen to avoid.

Each one of the above steps increases the milling cost and is "saved" when skipped. So the production cost becomes lower. The problem is this difference in cost is not passed on to you, the consumer. It does not go to the miller who works for pennies, or to the farmer who has toiled in the grove. This money is pocketed by the oil merchant who brings a sludgy, low quality oil to the UK and sells it on as if it was a premium product.

There is no romance in a dirty, neglected mill that is run haphazardly. Grime does not make olive oil real.

OPUS is milled artisanally in individual batches in a small, but state of the art, successful mill, run by the most meticulous people in the Greek olive oil world and overseen by a certified specialist olive oil sommelier. It takes a village to make the best artisanal olive oil, everyone needs to work well together: the people tending the trees in the olive grove, the millers maintaining the equipment in top condition and the olive oil specialists fine-tuning the calibrations of the equipment for the best possible quality outcome in any harvest year. Nothing less.

With us your olive oil is nothing but pure olive juice, free of any unpleasantness.

Buy OPUS for peace of mind.